BSP Thread Gauges Explained: Types, Advantages, and Best Practices

Introduction

In the world of engineering and manufacturing, precision and accuracy are paramount. This is especially true when it comes to threaded components, where even the tiniest deviation can lead to functional issues and compatibility problems. BSP thread gauges play a crucial role in ensuring that threaded connections are precise and reliable. In this comprehensive guide, we'll delve into the intricacies of BSP thread gauges, exploring their types, advantages, and best practices for optimal performance.

Understanding BSP Thread Gauges

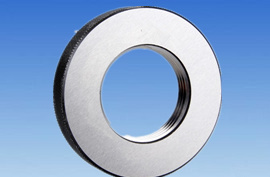

What are BSP Thread Gauges?

BSP, or British Standard Pipe, thread gauges are precision instruments used to measure and inspect the characteristics of threaded components conforming to the British Standard Pipe thread standards. These standards encompass both parallel and tapered threads, commonly used in a wide range of applications, including plumbing, hydraulic systems, and pneumatic systems.

Types of BSP Thread Gauges

There are two primary types of BSP thread gauges: Parallel and Tapered.

1. Parallel BSP Thread Gauges

Parallel BSP thread gauges, also known as cylindrical thread gauges, are used to measure the dimensions and characteristics of parallel threads. These threads maintain a constant diameter along the length of the component and are commonly found in applications where a reliable seal is required, such as plumbing connections.

2. Tapered BSP Thread Gauges

Tapered BSP thread gauges, on the other hand, are designed for measuring tapered threads. These threads have a decreasing diameter along their length and are commonly used in situations where a secure and leak-free connection is essential, such as gas fittings.

Advantages of Using BSP Thread Gauges

Using BSP thread gauges offers a plethora of advantages that contribute to the efficiency and reliability of threaded connections.

1. Precision Measurement

BSP thread gauges are manufactured to strict standards, ensuring accurate measurement of thread characteristics. This precision leads to consistent and reliable connections, minimizing the risk of leaks or functional issues.

2. Compatibility Assurance

By using BSP thread gauges, manufacturers can ensure that their threaded components adhere to industry standards. This, in turn, guarantees compatibility with other components, reducing the chances of costly errors and rework.

3. Enhanced Sealing

In applications where sealing is critical, such as fluid or gas systems, BSP thread gauges help achieve an effective seal between threaded components. This prevents leakage and maintains system integrity.

4. Reduced Downtime

Accurate thread measurements obtained through BSP thread gauges lead to smoother assembly processes. This reduction in errors and rework translates to shorter downtime and increased productivity.

Best Practices for Using BSP Thread Gauges

To make the most of BSP thread gauges and ensure optimal performance, it's essential to follow some best practices.

1. Proper Calibration

Regularly calibrating your BSP thread gauges is crucial for accurate measurements. Calibration ensures that the gauges maintain their precision over time, resulting in reliable thread inspections.

2. Clean and Lubricated Threads

Before conducting measurements, ensure that the threads are clean and free from debris. Applying a suitable lubricant can further enhance the accuracy of measurements and prevent thread damage.

3. Correct Gauge Selection

Choosing the right type and size of BSP thread gauge is fundamental. Using the wrong gauge can lead to incorrect measurements and compatibility issues.

4. Controlled Environment

Perform thread measurements in a controlled environment to minimize external factors that could affect accuracy. This includes proper lighting, temperature, and cleanliness.

Conclusion

In conclusion, BSP thread gauges are indispensable tools for industries that rely on threaded connections. Whether you're working with fluids under pressure or require standardized thread measurements, BSP thread gauges offer a range of benefits that enhance the quality and reliability of your applications. By understanding the types, advantages, and best practices associated with BSP thread gauges, you can confidently make informed decisions that contribute to the success of your projects. For more informative articles on various industrial topics, visit https://www.gaugestools.com.

Comments

Post a Comment