Let’s Get To Know About Thread Ring Gauge Manufacturers And Their Various Uses!!

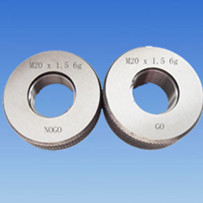

T hread ring gauges are metrology devices that are utilized for gauging the external diameters of pins, shafts, splines, clasp, dowels, studs, and other machined round and hollow parts. The best thread ring gauge manufacturers such as Gauge Tools , make these gauges typically cylindrical and fabricate them from a steady material (ordinarily apparatus steel) with an exceptionally exact (extremely high-resistance) bore in their middle that works as the gauge for the external diameter of the parts. The key role of thread ring gauge manufacturers is to build upon a go/no-go basis whether the part being gaged falls inside the dimensional resilience that was indicated for it. The utilization of ring gauges empowers examinations and quality choices about machined parts to be made rapidly without the need to resort to the utilization of micrometers, calipers, thickness checks, or other estimation instruments that could take more time to yield an outcome. Thread ring gauges and ...