Everything You Should Know About Is Go No Go Thread Gauge

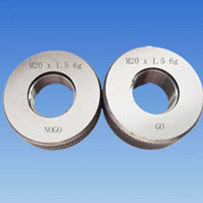

Ga u ges are frequently used to examine threaded holes and shafts. While testing threaded holes in manufactured parts with plug gauges is a regular procedure, it is also crucial to check the diameter of shafts, dowels, and fasteners with ring gauges. For examining non-threaded items, there are additional smooth ring gauges. Ring gauges offer a go/no-go evaluation of the pins, shafts, or threaded studs' stated dimensional tolerances or characteristics. Ring gauges are used in a range of industries, such as machine tools, automotive, oil and gas exploration, and other metal working applications, for comparative gauging as well as for the checking, calibrating, or establishing of gauges or other standards. What Is Go No Go Thread Gauge The no-go thread ring gauge is made to determine whether the work piece’s real external thread pitch diameter is smaller than the minimum size required. The major and minor sizes of the exterior thread are not examined here. The thread length of the no-...