IMPORTANCE OF THREAD PLUG GAUGE SUPPLIERS

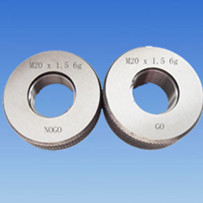

Thread plug gages also thread plug gauges are used to examine the major diameter and pitch diameter inside threaded parts. There is a certain specification and to check the tolerances of the threaded parts thread plug gauges are used. They provide accurate measurements with perfect results. There are many thread gaging instruments or tools such as thread ring gages, measuring wire, screw thread insert, tri-roll comparators, measuring wire, thread micrometers. Thread micrometers are used for measuring micrometers of thread. A tri roll uses three thread rolls and a digital display. The automotive industries make use of STI gages. Thus, the items produced are used by various industries for explicit applications dealing with different measurements and hence the production must be in the highest possible accuracy. The benefits of using thread plug gauge are numerous hence thread plug gauge suppliers are in high demand. Easy use : - Thread plug gauges are very efficient as they prov...