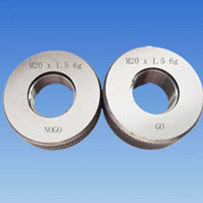

Choosing your GO NO GO Thread Gauge provider A GO NO-GO thread gauge refers to an inspection tool used to check the tolerance of a workpiece or tool to its given t via a go/no-go test. Its name is derived from two tests: the check involves the workpiece having to pass one test (go) and fail the other (no-go). The standards for the gauge and thread for the checking of the workpiece or tool strength is set by the ISO. The modern times demand efficiency from every little profession and this efficiency is driven out from the tools. Checking the tolerance of these tools thus makes for an important task. Though there have come up a number of different service providers of the GO No Go thread gauge to all the customers out there. This further complicates the situation as it gets difficult to make the choice of a quality product provider. A few factors that have to be sought from your service provider could be listed as such:- - Return policy : - The top quali