3 Important Applications of the Thread Gages

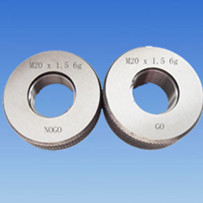

While working on the job site, you will come across many tools and equipment. One cannot always understand all the equipment since; it is impossible. These can involve what kind of pitch of the thread you are dealing with. It can be quite extremely difficult to find precisely what you require when dealing with the threaded items, especially if you are trying to look for just one single screw, piece of pipe, or bolt in the middle of a bunch of other forms. There is a device named thread gage which can help you decide which to use. You will across many thread gage manufacturers around you that can provide you with the same. Let us look at its uses. GO/NOGO The GO/NOGO gages are being used to evaluate whether the threads on the external surface of threaded components (screws and bolts) adhere to the threads on their corresponding internal threaded components (nuts or holes). They do this by deciding the pitch, angle, and lead of the thread correctly. The gage for a specific com