Accurately Using Your Thread Plug Gauge: Pointers to Consider

Because you are tasked with more significant responsibilities when you work as an industrial assembly operator, you are expected to think about more than just your profit. Because modules manufactured by your company are likely to be used in a variety of industries and for a wide range of specific applications, the accuracy with which your production line operates is of the utmost importance.

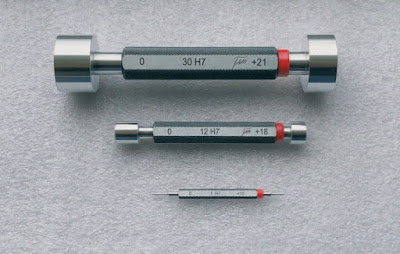

If you want to be successful in reaching that objective, you will need to ensure that all of your gear is proportionately sized. Even though other technologies currently available on the market make claims to be helpful in this industry, thread plug gauges continue to be the gold standard.

When it comes to choosing the right thread plug gauge for your needs, it's important to select one that is accurate and fit for purpose. There are a few things to consider when making your selection to ensure you get the best possible results.

The first thing to consider is the type of material the gauge is made from. There are a few different options available, each with their own advantages and disadvantages. The most common materials used for thread plug gauges are steel, brass, and plastic.

Steel is the most durable option and can withstand the highest amount of wear and tear. However, it is also the most expensive option. Brass is a good middle-ground option that is more affordable than steel but still has good durability. Plastic is the most affordable option but is also the least durable.

The second thing to consider is the accuracy of the gauge. There are a few different ways to measure accuracy, but the two most common are either by using a micrometer or by using a vernier caliper.

A micrometer is more accurate than a vernier caliper, but it is also more expensive. If accuracy is your top priority, then a micrometer is the way to go. A vernier caliper is less expensive and still provides good accuracy for most purposes.

The third thing to consider is the size of the gauge. There are a few different sizes available, but the most common are 1/8", 1/4", 3/8", and 1/2".

The size of the gauge you need will depend on the thread you are measuring. If you are measuring a standard thread, then a 1/8" gauge will likely be sufficient.

If you are measuring a metric thread, then a 3/8" gauge will likely be necessary. Finally, you will need to decide on the unit of measurement you want to use. The most common units of measurement for thread gauges are in mm or inches. Once you have considered all of these factors, you should be able to choose the best thread plug gauge for your needs.

Some additional factors to remember:

Using a thread plug gauge is simple: just insert the plug into the thread and see which one fits the best. However, there are a few things to keep in mind in order to get accurate measurements:

- Make sure the thread plug gauge is clean before use. Any dirt or debris on the plugs can throw off the measurement.

- Insert the plug all the way into the thread. If the plug is not inserted far enough, the measurement will be inaccurate.

- Be sure to check the gauge regularly for wear. The plugs can become worn with use and will no longer give accurate readings if they are not replaced.

Following these simple tips will help ensure that your thread plug gauge is giving you accurate readings and that your product is of the highest quality.

Conclusion:

It is important to remember that the thread plug gauge can be used in several different ways, from checking the efficacy of a particular type of thread on a specific piece of equipment to verifying the proper assembly of various parts and subassemblies. To get a quality thread plug gauge, it is essential to choose a reputed Thread Plug Gauge Manufacturer. Because of the importance that threaded holes have in manufacturing, it is important to make sure that they are as well-made as possible. However, this does not always happen. Moreover, there is a good chance that your thread plug gauge will be damaged if you try to use it on a poorly-made threaded hole.

Comments

Post a Comment